Knowde Enhanced TDS

Identification & Functionality

- Additives Included

- Base Oil Type

- Chemical Family

- Chemical Name

- Product Type

- Cleaning Ingredients Functions

- Industrial Additives Functions

- Plastics & Elastomers Functions

- CAS No.

- 9006-65-9

- EC No.

- 618-433-4

- Product Families

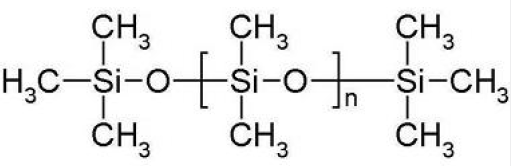

- Chemical Structure

Features & Benefits

- Labeling Claims

- HII Features

- Industrial Additives Features

- Materials Features

Applications & Uses

- Markets

- Applications

- Home Care Applications

- Industrial Additives End Use

- Application Details

- Due to WACKER® AK 100 many diverse applications, no general processing information can be provided. Parameters will vary from application to application.

- Available in a range of viscosities, WACKER® SILICONE FLUIDS AK are miscible with each other in any ratio. The standard product's viscosity can thus be altered to suit your individual needs.

- WACKER® AK 100 is a non-polar liquid and is immiscible with polar solvents such as water or short-chain alcohols.

- In aliphatic and aromatic hydrocarbons, chlorohydrocarbons, ethers, esters, ketones and higher alcohols, WACKER® AK 100 is soluble in any proportion.

- Before the product is used with solvents for the first time, it is advisable to perform a lab-scale test.

- When solvents are used, please remember to read the appropriate hazard information.

- Release agent

- Lubricant

- Hydraulic fluid

- Antifoam agent

- Water-repellent agent

- Liquid dielectric for electrical and electronic equipment

- Heat-transfer oil

- Polish additive

- Plastics additive

- Additive for textile and fiber auxiliaries

- For pharmaceutical applications, we recommend specialty silicone fluids from our SILFAR® line.

- Silicone fluids from our BELSIL® line are available for the cosmetic sector.

- Whenever particularly high heat and shear resistance is required, we recommend silicone fluids from our AK stab, AK visc and AKC product lines.

- Specialty grades of the product (available as WACKER® PLASTICIZER) will be needed for use as a silicone plasticizer in RTV-1 sealants

Properties

- Color

- Physical Form

- Appearance

- Clear colorless liquid

- Typical Properties

- Properties

- Minimal change in physical properties over a broad temperature range

- Excellent water-repellent properties

- Good dielectric properties

- Low surface tension and thus high surface activity

- Chemically highly unreactive

- Low solidifying point

- High flash point

- High heat resistance

- Good solubility in a wide range of solvents

| Value | Units | Test Method / Conditions | |

| Density (at 25°C) | approx. 0.96 | g/cm³ | DIN 51757 |

| Flash Point | min. 275 | °C | ISO 2592 |

| Kinematic Viscosity (at 25°C) | approx. 100 | mm²/s | DIN 53019 |

| Refractive Index (at 25°C) | approx. 1.403 | — | — |

| Surface Tension (at 25°C) | approx. 0.021 | N/m | — |

Regulatory & Compliance

- Certifications & Compliance

Packaging & Availability

- Country Availability

- Regional Availability